Membrane switch in consumer electronics: manufacturing considerations

Recognizing the Value of Membrane Switch in Modern Electronic Devices

Membrane switches are indispensable parts in contemporary digital tools. They use a blend of functionality and layout that enhances user interaction. Their lightweight and sturdy nature makes them appropriate for numerous applications. As markets evolve, the demand for customization and progressed features grows. Understanding just how membrane layer changes add to advancement reveals their value fit the future of electronics. What exists in advance for this innovation?

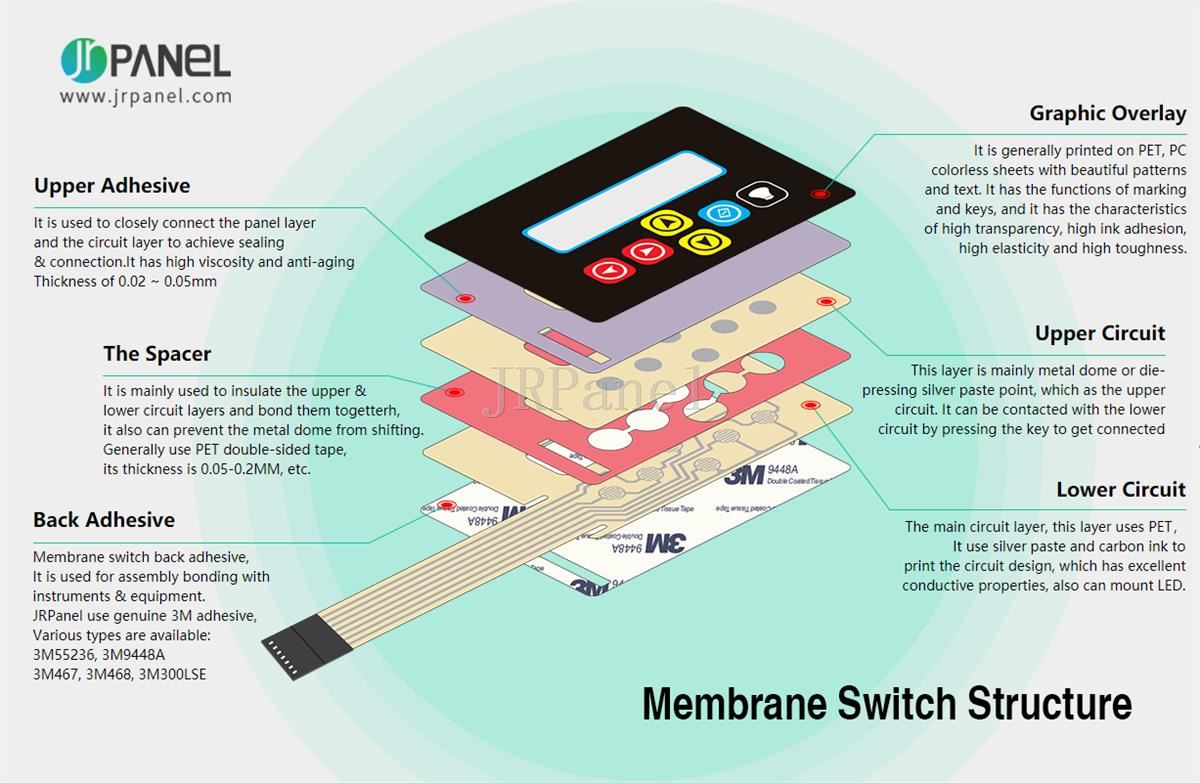

The Basics of Membrane Layer Switch Technology

Commonly neglected, membrane button innovation plays an important duty in the modern electronic devices landscape. These devices, composed of numerous layers, function as individual interfaces for numerous electronic items, ranging from household devices to clinical tools. A regular membrane button includes a visuals overlay, a spacer layer, and a circuit layer, which are diligently put together to develop a functional interface.When pressure is put on the overlay, the circuit layer is completed, permitting signals to be transmitted to the device. This technology is recognized for its flexibility, enabling modification in capability, design, and shape to meet particular individual requirements. In addition, membrane switches are slim and light-weight, making them ideal for applications where room is a premium. Their longevity and resistance to ecological factors even more boost their charm, ensuring they can stand up to harsh problems while keeping capability. Overall, membrane layer button modern technology is essential to creating user-friendly and reliable digital devices

Key Benefits of Membrane Changes

Membrane switches over deal a number of essential advantages that make them a recommended choice in various digital applications. Their design enables a portable type factor, enabling manufacturers to develop lightweight and streamlined devices. In addition, membrane buttons are immune to dust, wetness, and chemicals, which enhances their resilience and longevity in demanding settings. The responsive responses offered by these buttons can enhance individual experience, making them easy and instinctive to operate.Furthermore, membrane buttons can be customized with varied graphics and colors, permitting for distinct branding possibilities. The manufacturing procedure is normally cost-effective, particularly for high-volume manufacturing, as it lowers assembly time and streamlines design. Membrane switches over require very little maintenance, adding to reduced total functional costs. These advantages highlight their expanding appeal in modern electronic devices, where integrity and straightforward interfaces are important.

Applications Throughout Numerous Industries

The versatility of membrane layer switches over enables their widespread fostering across numerous markets. In the medical area, they are commonly used in analysis equipment and person monitoring systems, offering a sturdy interface immune to contaminants. The automotive sector uses membrane layer buttons for control panel controls, enhancing customer experience with sleek designs that withstand extreme problems. In consumer electronic devices, they offer as control panels for gadgets such as microwaves and coffee makers, providing an easy to use user interface that is easy to tidy. The aerospace industry utilizes membrane layer switches in cockpit controls, where dependability and room efficiency are paramount. Furthermore, the commercial industry leverages these buttons in machinery and control systems to ensure durable operation popular environments. This broad variety of applications emphasizes the adaptability of membrane buttons, making them essential parts in enhancing performance and customer communication across varied technical landscapes.

Customization and Layout Versatility

Future Trends in Membrane Layer Change Development

Arising patterns in membrane button growth show an expanding focus on enhanced performance and assimilation with wise technologies. As consumer need for more innovative electronic tools boosts, suppliers are focusing on developing membrane switches over that not just offer basic functional roles yet also incorporate attributes like touch sensitivity, backlighting, and haptic feedback.Furthermore, click site advancements in products are expected to improve resilience and ecological resistance, making membrane changes appropriate for diverse applications in industries such as medical care, automotive, and customer electronic devices. The integration of capacitive touch technology is most likely to come to be more prevalent, enabling for sleeker styles and enhanced customer interfaces. membrane switch.Additionally, the surge of the Internet of Points (IoT) is triggering the growth of membrane layer changes that can connect wirelessly with various other tools, enhancing interconnectivity. On the whole, the future of membrane switch modern technology appears encouraging, driven by development and the search of user-friendly services

Regularly Asked Questions

Just How Do Membrane Switches Over Compare to Conventional Mechanical Buttons?

Membrane switches, being much more space-efficient and providing a smooth design, comparison with typical mechanical buttons that provide responsive responses. The previous typically feature customizable graphics, while the last typically ensure longevity and integrity in numerous applications.

What Materials Are Typically Utilized in Membrane Layer Switch Over Production?

Membrane layer switches are commonly generated utilizing products such as polyester, polycarbonate, and printed conductive inks. These materials give flexibility, durability, and responsiveness, making them ideal for numerous applications in electronic gadgets and individual interfaces.

Can Membrane Switches Be Fixed or Reused?

Membrane switches can frequently be repaired, especially if minor issues emerge, such as adhesive failure or surface area damages. Nonetheless, full reuse is generally restricted because of put on and potential deterioration of products over time.

Just How Do Environmental Elements Affect Membrane Switch Performance?

Ecological factors, such as exposure, moisture, and temperature to chemicals, significantly affect membrane switch efficiency. Severe problems can cause destruction, impacting responsiveness and durability, inevitably jeopardizing the functionality of the tool in numerous applications.

What Is the Normal Life Expectancy of a Membrane Layer Switch?

The common life-span of a membrane button generally varies from 1 to 5 million actuations, depending upon variables such as use regularity, ecological conditions, and the materials utilized in production, impacting durability and efficiency long life. A typical membrane switch is composed of a graphic overlay, a spacer layer, and a circuit layer, which are thoroughly constructed to develop a practical interface - membrane switch.When stress is used to the overlay, the circuit layer is finished, permitting signals to be transferred to the tool. The tactile feedback provided by these switches can improve customer experience, making them simple and user-friendly to operate.Furthermore, membrane layer buttons can be tailored with varied graphics and colors, enabling for one-of-a-kind branding possibilities. As consumer need for extra innovative digital devices rises, manufacturers are focusing on creating membrane layer changes that not just offer fundamental functional functions but also incorporate features like touch sensitivity, backlighting, and haptic feedback.Furthermore, developments in products are expected to enhance resilience and environmental resistance, making membrane layer switches see this site ideal for varied applications in markets such as health care, auto, and customer electronics. The integration of capacitive touch technology is likely to end up being much more common, enabling for sleeker layouts and enhanced user interfaces.Additionally, the rise of the Internet of Things (IoT) is prompting the growth of membrane layer changes that can connect wirelessly with various other gadgets, enhancing interconnectivity. Membrane layer buttons, being extra space-efficient and using a smooth layout, comparison with typical mechanical buttons that offer responsive feedback